OEM/ODM China Vacuum Evaporator - Multi effect falling film evaporator – Weitai

OEM/ODM China Vacuum Evaporator - Multi effect falling film evaporator – Weitai Detail:

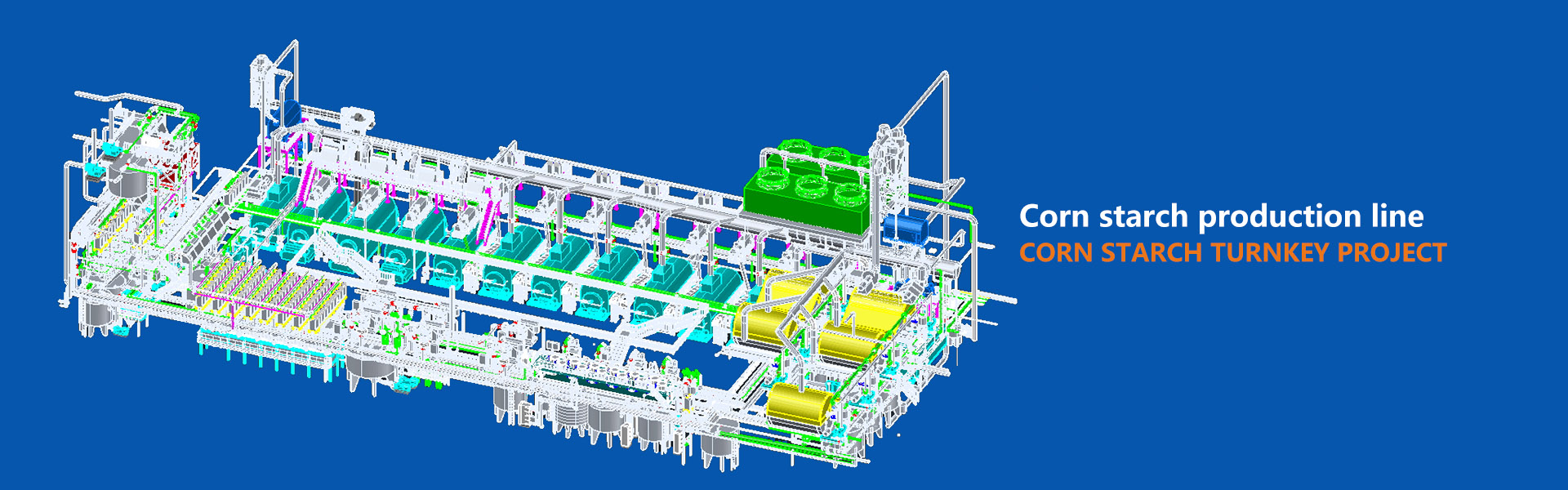

The multi effect falling film evaporator uses the falling film evaporation principle to heat and boil the dilute solution to vaporize part of the water to achieve the purpose of concentrating the solution. This unit adopts continuous production process, which has the advantages of large concentration ratio (1 / 5-1 / 10), wide viscosity range (<400CP), good heat transfer effect, large processing capacity, etc., suitable for heat sensitivity, high concentration, viscosity The evaporation of large and corrosive materials is suitable for the concentration of corn syrup and malt juice in the starch industry, fruit juice and monosodium glutamate in the food industry, milk in the dairy industry, sugar juice in the sugar industry and distillate filtrate in the alcohol industry.

This unit has a large heat transfer coefficient and requires a small difference in heat transfer temperature. Depending on the nature of the evaporation material and the evaporation target, it can be combined into a double-effect, three-effect, four-effect, and five-effect evaporation system. It can also use tube bundles or coils. The waste steam on the top of the dryer and other low heating value heat sources (such as condensed water vapor) are used as the heat source of the evaporator to become the waste heat evaporator, thereby greatly reducing the amount of steam generated and achieving the maximum energy saving effect. When there is a sufficient supply of waste heat steam, steam generation can be completely eliminated, and the economic benefits are significant.

Technical Parameter

| Specifications | WTJM-3 | WTJM-6 | WTJM-9 | WTJM-10 | WTJM-15 | WTJM-20 | WTJM-30 | WTJM-50 |

| Evaporating Capacity(kg/h) | 3000 | 6000 | 9000 | 10000 | 15000 | 20000 | 30000 | 50000 |

| Steam pressure(Mpa) | 0.6-1.0 | |||||||

| Steam cost(kg/h) | 900 | 1600 | 2200 | 2400 | 3300 | 4200 | 6000 | 10000 |

| Input DS(%) | 26-30(glucose syrup) | |||||||

| Output DS(%) | 70-75 | |||||||

| Vacuum degree(Mpa) | Evaporation temperature(℃) | |||||||

| First effect | 0.01-0.03 | 90-110 | ||||||

| Second effect | 0.03-0.05 | 75-85 | ||||||

| Third effect | 0.05-0.07 | 65-75 | ||||||

| Fouth effect | 0.07-0.09 | 50-60 | ||||||

Product detail pictures:

Related Product Guide:

owing to good service, a variety of high quality products, competitive prices and efficient delivery, we enjoy a good reputation among our customers. We are an energetic company with wide market for OEM/ODM China Vacuum Evaporator - Multi effect falling film evaporator – Weitai , The product will supply to all over the world, such as: Japan, Japan, Uruguay, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve products and provide more comprehensive services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.