Good Quality Static Sieve Bend Screen - Pressure arc sieve – Weitai

Good Quality Static Sieve Bend Screen - Pressure arc sieve – Weitai Detail:

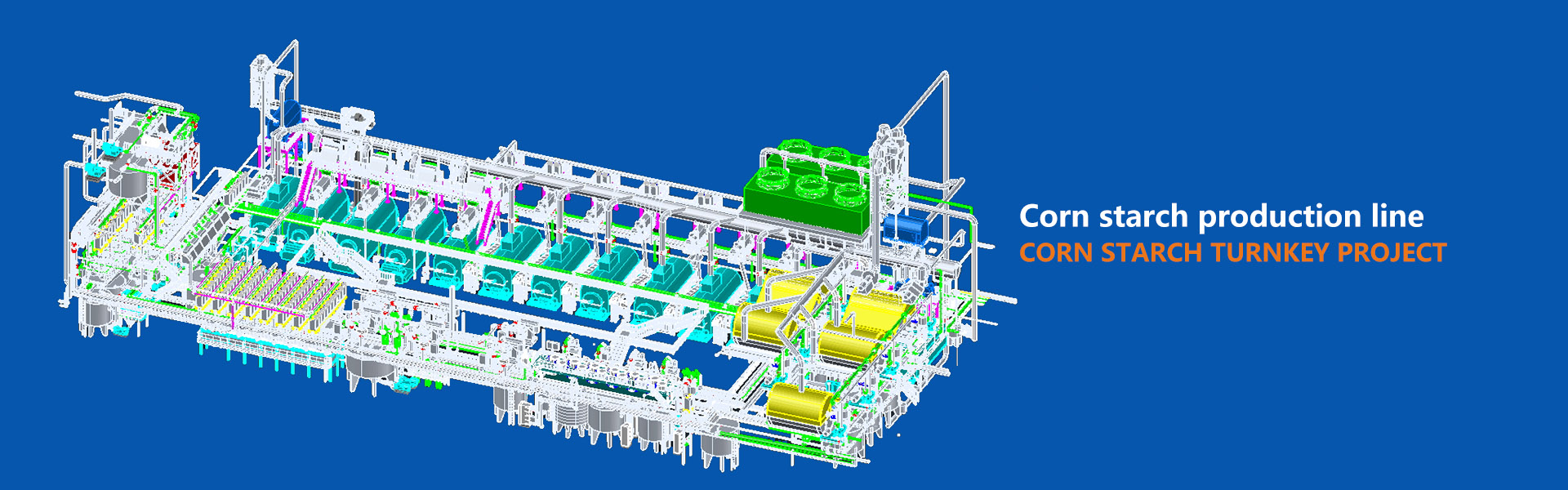

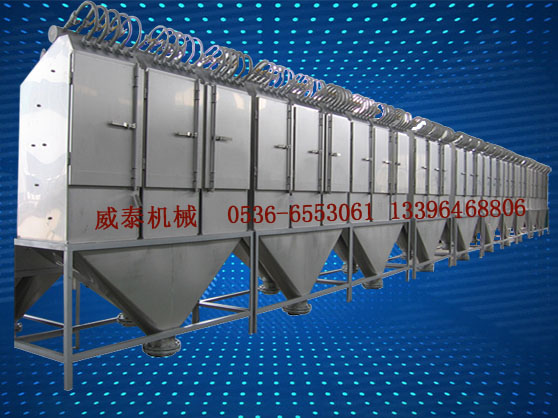

Pressure curved sieve is one of the most advanced starch equipment at home and abroad. The pressure curved sieve is screened by multi-access counter current washing process, which can effectively improve the powder yield and starch quality, has significant economic benefits.

Echnical parameters

| No. | Item | Single Unit | Duplex |

| 1 | Screen surface arc angle | 120° | 120° |

| 2 | Screen surface width | 50um/75um/100um/120um | 50um/75um/100um/120um |

| 3 | Material handling capacity | 42-57m³/h | 85-115m³/h |

| 4 | Feed pressure | 0.2-0.4Mpa | 0.2-0.4Mpa |

| 5 | Screen width | 585mm(710mm) | 585*2mm(710*2mm) |

| 6 | Screen radius | 762 mm | 762mm |

Pressure arc sieve is highly efficient fine sieve under certain pressure, applied in starch processing for multi-stage counter-current rinse, sieving and separation, dehydration and abstraction as well as elimination of solid-form substances and impurities.

It is widely used in corn starch processing plant.The equipment enables high rate of starch yield and improvement of starch quality and is an ideal new high quantity treating sieving and separating equipment for wet materials.

Pre-sale service

1. Introducing detail features and application of the products to customer.

2. Selecting economical and practical machines for customer.

3. Providing operation data of the related machine.

4. Providing means of trial performance for customer.

5. Flow chart and factory designing layout.

Sale service

1. Recommending engineering conditions required for installation of the machine.

2. Communicating the manufacturing progress of machines with customer in time.

3. Project planning and design services.

After-sale service

1. Training of equipment maintenance and operating personally.

2.Installation and commissioning of equipment until everything is functional.

3. One year warranty and Providing long-term maintenance service and spare parts.

4. Giving technical support to customer for developing new product.

5. Provide English Version of Installation/Operation/Service/Maintenance Manual.

Bending machine construction site & shearing machine

Product detail pictures:

Related Product Guide:

we are able to supply top quality items, aggressive price and greatest buyer assistance. Our destination is You come here with difficulty and we offer you a smile to take away for Good Quality Static Sieve Bend Screen - Pressure arc sieve – Weitai , The product will supply to all over the world, such as: Cologne, India, Namibia, We pay high attention to customer service, and cherish every customer. We have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!