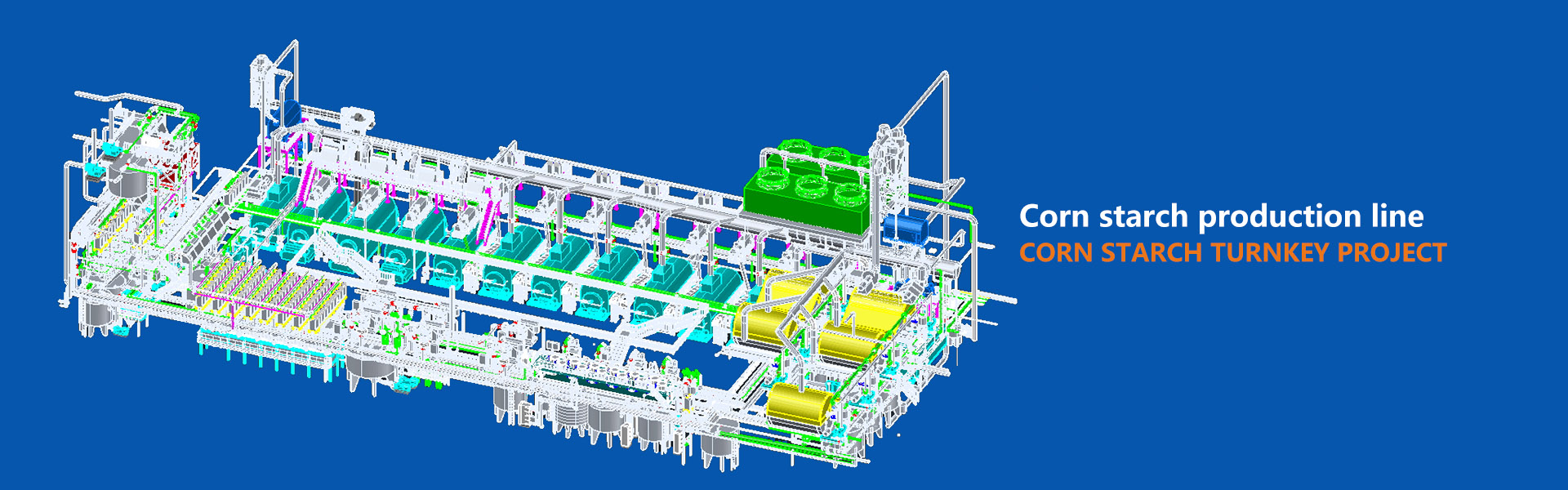

Good Quality Gravity Arc Sieve - Gravity arc sieve – Weitai

Good Quality Gravity Arc Sieve - Gravity arc sieve – Weitai Detail:

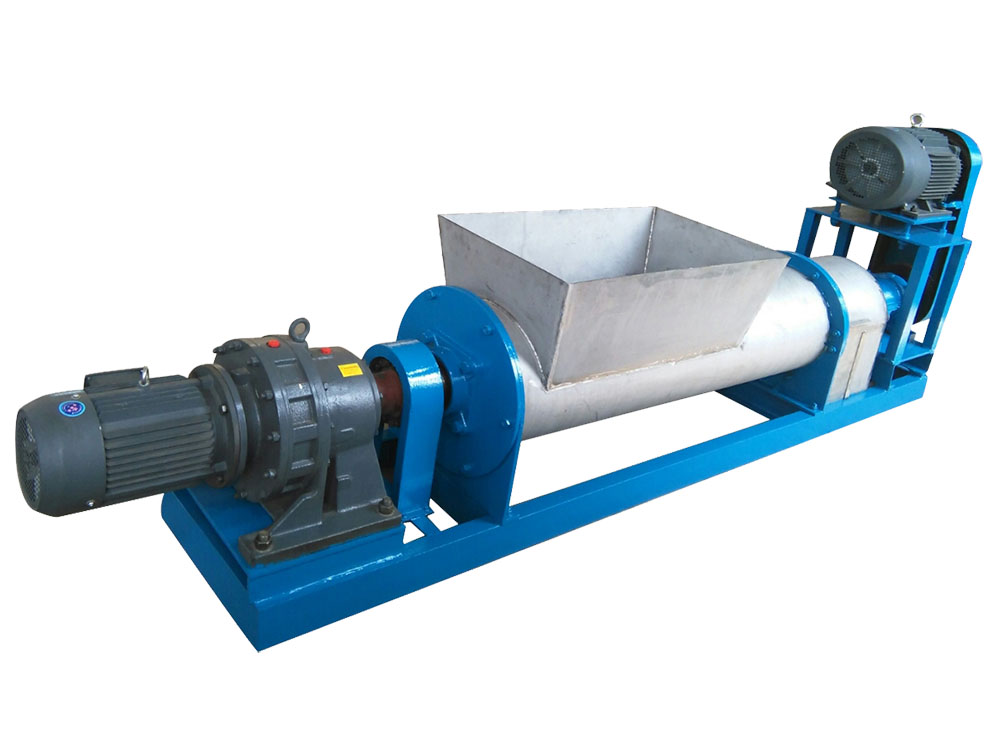

QZ series gravity screen is a new high-efficiency screening machine. Its main working part is a concave screen surface with certain radian. The screen is made by splicing some stainless steel wedge-shaped bars together. This sieve bend is competent in finishing screening, dewatering, cleaning, extraction, and solid impurity removal in heavy-duty screening occasions. It has found great popularity in corn dewatering, corn germ dewatering and cleaning, and crude/fine fiber separation in starch industry.

The mixture flows along the curved screen surface under the action of gravity and is distributed evenly on the whole screen surface. When the materials perform circular motion, the centrifugal force generated by the small particles is larger than the inertial force, so the materials penetrate though the screen slog and discharged from the lower port. Particles whose size is larger than the slog’s will be left on the screen surface and discharged from the upper port. In this process, the main power source is only the materials gravity, that’s why the machine is called gravity screen.

Structure of Gravity Screen

Gravity screen is mainly consisted of frame and screen. For the upper body of the screen, we have set a receiving trough, which is equipped with overflow weir and pressure valve. The lower screen body adopts both upper and lower discharging ports. The screen is comprised of wedge-shaped screen bands and upper/lower blocking strips. Support rods are available back the screen bands. The screen is placed on the panels of the machine along the curbed pallets, and fixed by upper/lower blocking plates. Above the screen, we have set a movable cover. Central angle of the curved screen surface: 50°/45°; radius: 917mm/2038mm; screen length: 800mm/1600mm; screen width: 400mm, 600mm, 1000mm, 1200mm, 1500mm and 1800mm. Additionally, according to different installation methods and structures, gravity screen can be classified as A, B, and C types.

How to Choose the Right Gravity Screen

1. Screen width

The production capacity of ZQW gravity screen provided by Johnson Group (sieve bend manufacturer in America) is 115~570 L/min.inch (22.6~112.2L/h•mm). During production, users should determine the width of screen according to the material flow and production capacity (per unit) recommended above. Solid load and slog width are also important factors.

2. Slog width

Gravity screen is commonly used for corn dewatering, germ cleaning, and germ dewatering. Different slog width is prepared for different applications.

Screen for corn dewatering: 2.5mm~3.0mm

Screen before the secondary grinding: 0.6mm~1.0mm

Screen for corn germ: 0.75mm

Screen for germ cleaning: 1.0mm

Screen for germ dewatering: 1.2mm~1.5mm

3. The feeding and installing style should be determined basing on the layout of the sieve bend.

Features

With a triple gravity screen, the steps of corn germ screening, cleaning, and dewatering are integrate into one. This machine can help to shorten the production line, and cut on the costs of material transmission equipment. Besides, it is easy operated.

Precautions of Use

1. The materials should be fed uniformly; multi pipes should be employed for feeding when the screen surface is wide enough

2. Operators should ensure that the pressure valve moves flexible so that the materials can be distributed uniformly on the whole screen surface.

3. The angle between the string of the screen and the horizontal plane has some effect upon the screening effect, which can be improved by reducing the angle to some extent.

Main technical performance

| Product name | QZ40 AB | QZ60ABC | QZ80 | QZ100C | QZ120C |

| Sieve angle | 50 | 50 | 50 | 50 | 50 |

| Sieve length | 800 | 800 | 800 | 800 | 800 |

| width | 400 | 600 | 800 | 1000 | 1200 |

| Sieve area | 0.32 | 0.48 | 0.64 | 0.8 | 0.96 |

| Curved screen radius | 917 | 917 | 917 | 917 | 917 |

| Overflow height | 520 | 520 | 520 | 520 | 520 |

Product detail pictures:

Related Product Guide:

We have our own sales team, design team, technical team, QC team and package team. We have strict quality control procedures for each process. Also, all of our workers are experienced in printing field for Good Quality Gravity Arc Sieve - Gravity arc sieve – Weitai , The product will supply to all over the world, such as: Senegal, United Kingdom, Melbourne, We're introduced as a one of the growing manufacture supplier and export of our merchandise. Now we have a team of dedicated trained experienced who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.