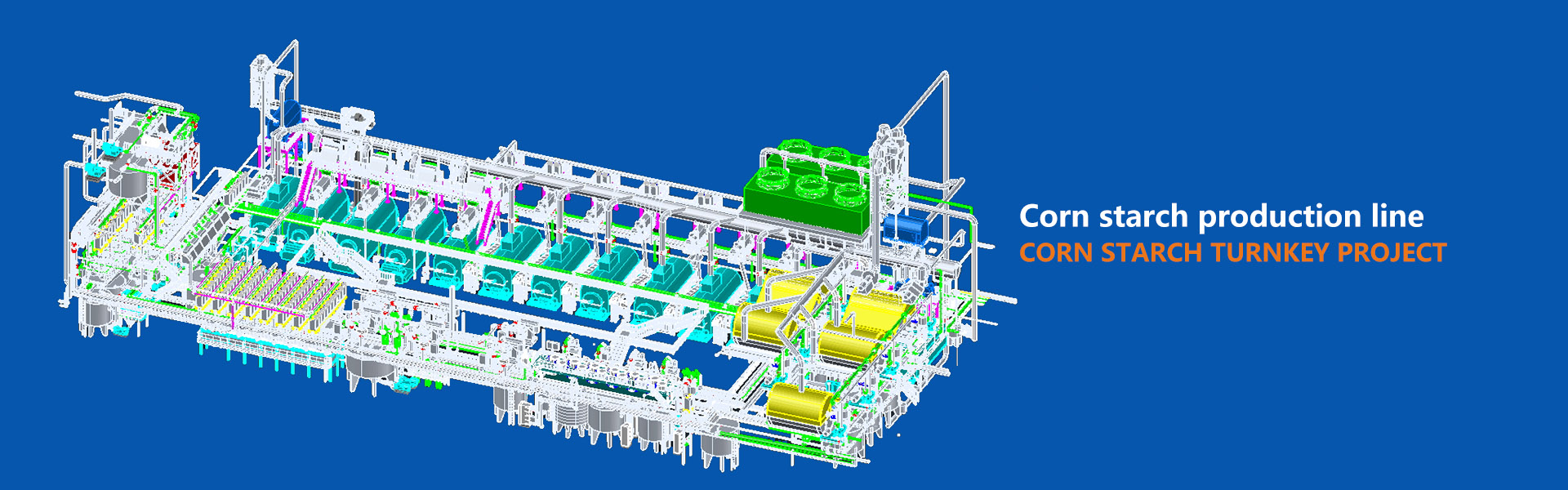

2020 High quality Corn Starch Milling Machine - Corn degerming mill – Weitai

2020 High quality Corn Starch Milling Machine - Corn degerming mill – Weitai Detail:

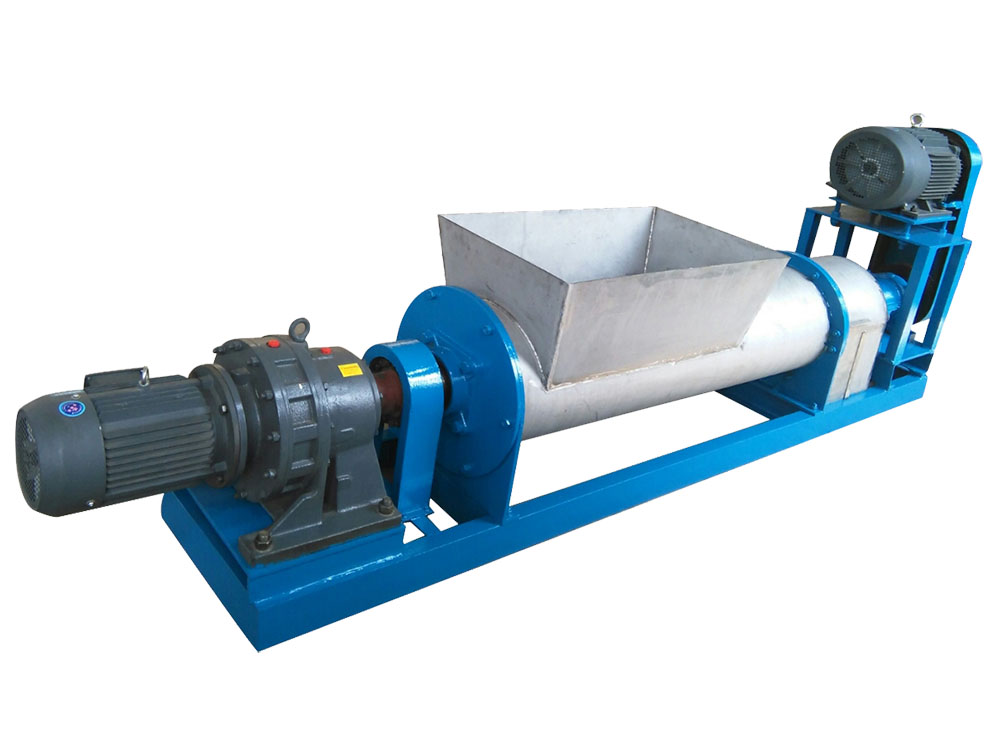

Working Principle

After a grinding process of the socked corn, the crushed corn pieces will fall into the grinding chamber through the inlet under the action of gravity, and then be thrown to the fixed and moving discs. Since the relative rotation of the 2 discs and the special layout of discs, the corn particles will bear a centrifugal force and be thrown out of the discs. In this process, the corn kernels rub and hit with each other to get crushed. While the mutual impact between the particles will have little influence on the corn’s germ, which is good for the separation of germ and reducing the fat content of starch.

It is mainly used for coarse crushing of corn kernels and germ corn kernels after reasonable soaking, so that the germ is separated from dander and endosperm. It is convenient to increase the yield of germ, in order to facilitate the subsequent fine grinding and starch refining. Due to the adjustable spacing, it can also be adapted to the coarse crushing of soybeans after soaking in soy products factory. The machine has simple structure, reliable sealing, stable performance and large output. The maintenance amount is the smallest compared with the same type of equipment, the energy consumption is the lowest, the operation and maintenance are convenient, and the self-protection function is provided.

The main technical parameters

| Type | Spindle speed(r/min) | Maximum adjustable distance of moving plate(mm) | Dynamic gear plate and turntable balance requirements |

| 800 Degerm mill | 980 | 60 | C≤0.16g |

| 1200 Degerm mill | 880 | 30 | C≤0.16g |

| Type | Broken once | Broken twice | ||||||

| output | Whole corn kernels | D-embryo rate | Degree of corn breakage | Processing capacity | Whole corn kernels | Germination rate | Degree of corn breakage | |

| 800 Degerming mill | 4-8T Commodity corn/H | 1% | 85% | 4-6 valve | 6-8TCommodity corn/H | Not allowed | 15% | 10-12 valve |

| 1200 Degerming mill | 20-25T Commodity corn/H | 25-30TCommodity corn/H | ||||||

Product detail pictures:

Related Product Guide:

Our products are greatly acknowledged and reliable by users and may fulfill repeatedly shifting financial and social wants for 2020 High quality Corn Starch Milling Machine - Corn degerming mill – Weitai , The product will supply to all over the world, such as: Ghana, Venezuela, Munich, Ensuring high product quality by choosing the best suppliers, now we have also implemented complete quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.